CANTEACH Selected Images.......

Previous Page

1 2

Click on the small images to see an enlarged view.

|

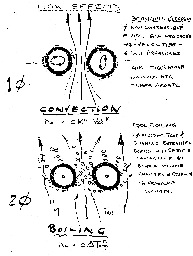

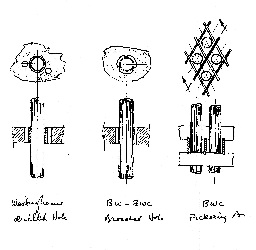

File info: source/45.jpg (size: 500 K)

Description: Sketch to explore a system of flexible bars as tube supports. Early in the BW Canada bid to AECL for the Pickering A design, it was clear to designer John Dyke that the Westinghouse and BW USA tube support systems (drilled holes and broach plates, respectively) were less than perfect. This and following sketch were developed to attempt to prove that the more flexible bars did do as proposed. Subsequently, a flexible lattice bar design was offered to AECL for Pickering A.

Source: [DYKE2005]

|

|

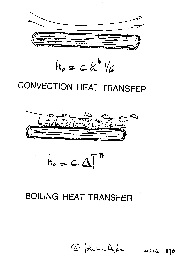

File info: source/46.jpg (size: 339 K)

Description:

Source: [DYKE2005]

|

|

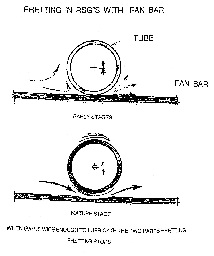

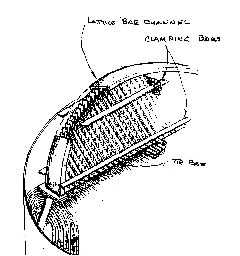

File info: source/47.jpg (size: 334 K)

Description: This sketch shows how a tube 'hard' against a lattice bar can vibrate and fret either the tube wall or the lattice bar to the point of failure. Fretting may stop if the flow is sufficient to open up a gap, keeping the parts separated with sufficient flow to lubricate the parts.

Source: [DYKE2005]

|

|

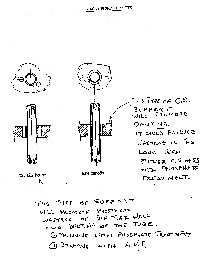

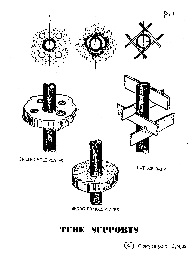

File info: source/49.jpg (size: 401 K)

Description: Single plane supports. This is a rigid support system and is not recommeded by Dyke.

Source: [DYKE2005]

|

|

File info: source/50.jpg (size: 155 K)

Description: Multi plane supports. This is a loose, flexible support system. This is the best means of tube support in two-phase flows, in the view of Dyke.

Source: [DYKE2005]

|

|

File info: source/53.jpg (size: 315 K)

Description: Comparison of multi plane and single plane supports. The multi plane support is a loose structure and it works well.

Source: [DYKE2005]

|

|

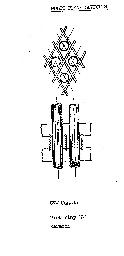

File info: source/54.jpg (size: 547 K)

Description: Typical tube support systems originally used in North America by the three boiler companies.

Pickering A: Lattice Bars

Pickering B: Broached Hole Plates

Bruce A & B: Broached Hole Plates

Darlington A: Originally Broached Hole Plates, changed to lattice bars due to the efforts of a few engineers.

Source: [DYKE2005]

|

|

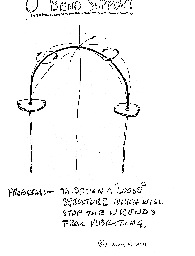

File info: source/58.jpg (size: 381 K)

Description: This sketch shows the many vibration modes of a U bend tube. One was concerned

how the supporting systems could take care of them all and these modes collaborated with (or not), with the vibrations in the tube bundle. Perhaps they worked to cancelled each other out. A wooden model was constructed to show these modes and videos were taken. Unfortunately the results were not pursued by the industry.

Source: [DYKE2005]

|

|

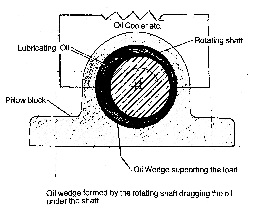

File info: source/60.jpg (size: 484 K)

Description: This is a sleeve bearing showing how the lubricant works to prevent metal to metal contact, and thus fretting.

Source: [DYKE2005]

|

|

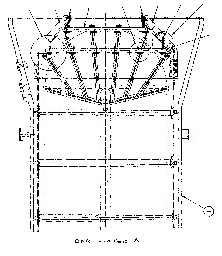

File info: source/69.jpg (size: 692 K)

Description: BW Canada U bend tube support for Darlington, circa 1979 (post John Dyke) to prevent fretting. Unfortunately, fretting occurs with this design.

Source: [DYKE2005]

|

|

File info: source/70.jpg (size: 411 K)

Description: Pickering A, 1965. Lattice bar U bend support, non-ridge design. No fretting was experienced in 20 years of operation.

Source: [DYKE2005]

|

|

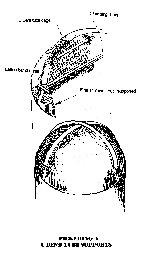

File info: source/71.jpg (size: 466 K)

Description: Pickering B, showing large and medium radii supports and an unsupported region.

Source: [DYKE2005]

|

|

File info: source/72.jpg (size: 906 K)

Description: Sketch for a proposed new design for U bend tube spacers.

Source: [DYKE2005]

|

|

File info: source/73.jpg (size: 344 K)

Description: Sketch of air stream hitting a tall circular stack which, if fitted with spacers, will reduce vortex shedding.

Source: [DYKE2005]

|

|

File info: source/75.jpg (size: 249 K)

Description: NPD fretting failure for single phase flows, the first in Canada.

Source: [DYKE2005]

|

|

File info: source/78.jpg (size: 217 K)

Description: Video shots of U bend support by flat bar spacers vibrating in air showing balanced tube motion side to side.

Source: [DYKE2005]

|

|

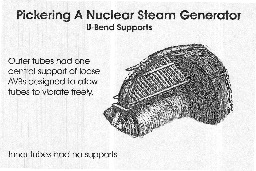

File info: source/79.jpg (size: 272 K)

Description: A cutaway view of Pickering A U bend tube support which had one partial set of loose lattice bars at the tube bundle centreline. The remainder of the tubes, which could support themselves, had no support at all. They were in service for 20 years without any failures.

Source: [DYKE2005]

|